El estándar

API 5L tiene como objetivo el gas y el agua en la industria del petróleo y el gas como referencia, que se utiliza para

tuberías de acero sin costura y

tuberías de acero soldadas, incluidos puertos y puertos comunes, puertos de toma de tuberías y tubos de flujo directo (TFL) y el puerto tiene para un particular Procesamiento de tubos de conexión.

El estándar API 5L incluye el grado de acero (GR.B, X42, X46, X52, X56, X60, X65, X70).

API 5L Standard tiene las disposiciones de los dos niveles de especificación de producto (PSL1 y PSL2). Los dos tipos de nivel de grado PSL del producto según el estándar estipulado en los requisitos técnicos de PSL2 de equivalente de carbono, dureza de muesca, límite elástico máximo y resistencia a la tracción tienen requisitos obligatorios. PSL es la abreviatura de nivel de especificación del producto. El nivel de especificación del producto de tubería de línea se divide en PSL1 y PSL2, también puede decir que los grados de calidad se dividen en PSL1 y PSL2. PSL2 por encima de PSL1, estos dos niveles no solo son diferentes requisitos de inspección y composición química, los requisitos de rendimiento mecánico son diferentes, por lo que el pedido en API 5 l, los términos del contrato además de indicar las especificaciones y el grado de acero generalmente indicadores, también debe indicar el nivel de especificación del producto, a saber, PSL1 o PSL2. PSL2 en composición química, propiedades de tracción, energía de impacto y pruebas no destructivas que son estrictas en los indicadores PSL1. PSL1 no requiere rendimiento de impacto, PSL2 todos excepto acero de grado x80, tamaño completo 0 ℃ promedio Akv: longitudinal p j, 41 agudeza lateral 27 j. Acero de grado promedio X80, tamaño completo 0 ℃ Akv: longitudinal 101 j, o agudeza lateral 68 j . La tubería de línea debe hacer una prueba de presión de agua, y los estándares no están permitidos para la generación no destructiva de presión hidráulica, que también es el estándar API y una gran diferencia entre el estándar de nuestro país. PSL1 no requiere la inspección no destructiva, PSL2 debe realizar un examen no destructivo .

|

Standard

|

Steel Grade

|

Yield Strength(MPa)

|

Tensile Strength(MPa)

|

|

API 5L

|

PSL1

|

A25

|

172

|

310

|

|

A

|

207

|

331

|

|

B

|

241

|

414

|

|

X42

|

290

|

414

|

|

X46

|

317

|

434

|

|

X52

|

359

|

455

|

|

X56

|

386

|

490

|

|

X60

|

414

|

517

|

|

X65

|

448

|

531

|

|

X70

|

483

|

565

|

|

PSL2

|

|

241-448

|

414-758

|

|

B

|

290-496

|

414-758

|

X42

|

317-524

|

434-758

|

X46

|

359-531

|

455-758

|

X52

|

386-544

|

490-758

|

X56

|

414-565

|

517-758

|

X60

|

448-600

|

531-758

|

X65

|

483-621

|

565-758

|

X70

|

552-690

|

621-827

|

Delivery condition:

|

PSL

|

Delivery Condition

|

Pipe grade

|

|

PSL1

|

As-rolled, normalized, normalizing formed

|

A

|

|

|

As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered or if agreed Q&T SMLS only

|

B

|

|

|

As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered

|

X42, X46, X52, X56, X60, X65, X70

|

|

PSL 2

|

As-rolled

|

BR, X42R

|

|

|

Normalizing rolled, normalizing formed, normalized or normalized and tempered

|

BN, X42N, X46N, X52N, X56N, X60N

|

|

|

Quenched and tempered

|

BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q

|

|

|

Thermomechanical rolled or thermomechanical formed

|

BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M

|

|

|

Thermomechanical rolled

|

X90M, X100M, X120M

|

|

|

The suffice (R, N, Q or M) for PSL2 grades, belongs to the steel grade

|

|

Chemical requirements:

Chemical Composition for PSL 1 pipe with t ≤ 0.984”

|

Steel Grade

|

Mass fraction, % based on heat and product analyses a,g

|

|

C

|

Mn

|

P

|

S

|

V

|

Nb

|

Ti

|

|

max b

|

max b

|

max

|

max

|

max

|

max

|

max

|

|

Seamless Pipe

|

|

A

|

0.22

|

0.9

|

0.3

|

0.3

|

–

|

–

|

–

|

|

B

|

0.28

|

1.2

|

0.3

|

0.3

|

c,d

|

c,d

|

d

|

|

X42

|

0.28

|

1.3

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X46

|

0.28

|

1.4

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X52

|

0.28

|

1.4

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X56

|

0.28

|

1.4

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X60

|

0.28 e

|

1.40 e

|

0.3

|

0.3

|

f

|

f

|

f

|

|

X65

|

0.28 e

|

1.40 e

|

0.3

|

0.3

|

f

|

f

|

f

|

|

X70

|

0.28 e

|

1.40 e

|

0.3

|

0.3

|

f

|

f

|

f

|

|

Welded Pipe

|

|

A

|

0.22

|

0.9

|

0.3

|

0.3

|

–

|

–

|

–

|

|

B

|

0.26

|

1.2

|

0.3

|

0.3

|

c,d

|

c,d

|

d

|

|

X42

|

0.26

|

1.3

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X46

|

0.26

|

1.4

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X52

|

0.26

|

1.4

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X56

|

0.26

|

1.4

|

0.3

|

0.3

|

d

|

d

|

d

|

|

X60

|

0.26 e

|

1.40 e

|

0.3

|

0.3

|

f

|

f

|

f

|

|

X65

|

0.26 e

|

1.45 e

|

0.3

|

0.3

|

f

|

f

|

f

|

|

X70

|

0.26e

|

1.65 e

|

0.3

|

0.3

|

f

|

f

|

f

|

a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; and Mo ≤ 0.15%,

b. For each reduction of 0.01% below the specified maximum concentration for carbon, an increase of 0.05% above the specified maximum concentration for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; and up to a maximum of 2.00% for grade L485 or X70.,

c. Unless otherwise agreed NB + V ≤ 0.06%,

d. Nb + V + TI ≤ 0.15%,

e. Unless otherwise agreed.,

f. Unless otherwise agreed, NB + V = Ti ≤ 0.15%,

g. No deliberate addition of B is permitted and the residual B ≤ 0.001%

|

Chemical Composition for PSL 2 pipe with t ≤ 0.984”

|

Steel Grade

|

Mass fraction, % based on heat and product analyses

|

Carbon Equiv a

|

|

C

|

Si

|

Mn

|

P

|

S

|

V

|

Nb

|

Ti

|

Other

|

CE IIW

|

CE Pcm

|

|

max b

|

max

|

max b

|

max

|

max

|

max

|

max

|

max

|

max

|

max

|

|

Seamless and Welded Pipe

|

|

BR

|

0.24

|

0.4

|

1.2

|

0.025

|

0.015

|

c

|

c

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X42R

|

0.24

|

0.4

|

1.2

|

0.025

|

0.015

|

0.06

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

BN

|

0.24

|

0.4

|

1.2

|

0.025

|

0.015

|

c

|

c

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X42N

|

0.24

|

0.4

|

1.2

|

0.025

|

0.015

|

0.06

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X46N

|

0.24

|

0.4

|

1.4

|

0.025

|

0.015

|

0.07

|

0.05

|

0.04

|

d,e,l

|

0.43

|

0.25

|

|

X52N

|

0.24

|

0.45

|

1.4

|

0.025

|

0.015

|

0.1

|

0.05

|

0.04

|

d,e,l

|

0.43

|

0.25

|

|

X56N

|

0.24

|

0.45

|

1.4

|

0.025

|

0.015

|

0.10f

|

0.05

|

0.04

|

d,e,l

|

0.43

|

0.25

|

|

X60N

|

0.24f

|

0.45f

|

1.40f

|

0.025

|

0.015

|

0.10f

|

0.05f

|

0.04f

|

g,h,l

|

As agreed

|

|

BQ

|

0.18

|

0.45

|

1.4

|

0.025

|

0.015

|

0.05

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X42Q

|

0.18

|

0.45

|

1.4

|

0.025

|

0.015

|

0.05

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X46Q

|

0.18

|

0.45

|

1.4

|

0.025

|

0.015

|

0.05

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X52Q

|

0.18

|

0.45

|

1.5

|

0.025

|

0.015

|

0.05

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X56Q

|

0.18

|

0.45f

|

1.5

|

0.025

|

0.015

|

0.07

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X60Q

|

0.18f

|

0.45f

|

1.70f

|

0.025

|

0.015

|

g

|

g

|

g

|

h,l

|

0.43

|

0.25

|

|

X65Q

|

0.18f

|

0.45f

|

1.70f

|

0.025

|

0.015

|

g

|

g

|

g

|

h,l

|

0.43

|

0.25

|

|

X70Q

|

0.18f

|

0.45f

|

1.80f

|

0.025

|

0.015

|

g

|

g

|

g

|

h,l

|

0.43

|

0.25

|

|

X80Q

|

0.18f

|

0.45f

|

1.90f

|

0.025

|

0.015

|

g

|

g

|

g

|

i,j

|

As agreed

|

|

X90Q

|

0.16f

|

0.45f

|

1.9

|

0.02

|

0.01

|

g

|

g

|

g

|

j,k

|

As agreed

|

|

X100Q

|

0.16f

|

0.45f

|

1.9

|

0.02

|

0.01

|

g

|

g

|

g

|

j,k

|

As agreed

|

|

Welded Pipe

|

|

BM

|

0.22

|

0.45

|

1.2

|

0.025

|

0.015

|

0.05

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X42M

|

0.22

|

0.45

|

1.3

|

0.025

|

0.015

|

0.05

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X46M

|

0.22

|

0.45

|

1.3

|

0.025

|

0.015

|

0.05

|

0.05

|

0.04

|

e,l

|

0.43

|

0.25

|

|

X52M

|

0.22

|

0.45

|

1.4

|

0.025

|

0.015

|

d

|

d

|

d

|

e,l

|

0.43

|

0.25

|

|

X56M

|

0.22

|

0.45f

|

1.4

|

0.025

|

0.015

|

d

|

d

|

d

|

e,l

|

0.43

|

0.25

|

|

X60M

|

0.12f

|

0.45f

|

1.60f

|

0.025

|

0.015

|

g

|

g

|

g

|

h,l

|

0.43

|

0.25

|

|

X65M

|

0.12f

|

0.45f

|

1.60f

|

0.025

|

0.015

|

g

|

g

|

g

|

h,l

|

0.43

|

0.25

|

|

X70M

|

0.12f

|

0.45f

|

1.70f

|

0.025

|

0.015

|

g

|

g

|

g

|

h,l

|

0.43

|

0.25

|

|

X80M

|

0.12f

|

0.45f

|

1.85f

|

0.025

|

0.015

|

g

|

g

|

g

|

i,j

|

.043f

|

0.25

|

|

X90M

|

0.1

|

0.55f

|

2.10f

|

0.02

|

0.01

|

g

|

g

|

g

|

i,j

|

–

|

0.25

|

|

X100M

|

0.1

|

0.55f

|

2.10f

|

0.02

|

0.01

|

g

|

g

|

g

|

i,j

|

–

|

0.25

|

a. SMLS t>0.787”, CE limits shall be as agreed. The CEIIW limits applied fi C > 0.12% and the CEPcm limits apply if C ≤ 0.12%,

b. For each reduction of 0.01% below the specified maximum for C, an increase of 0.05% above the specified maximum for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; up to a maximum of 2.00% for grades ≥ L485 or X70, but ≤ L555 or X80; and up to a maximum of 2.20% for grades > L555 or X80.,

c. Unless otherwise agreed Nb = V ≤ 0.06%,

d. Nb = V = Ti ≤ 0.15%,

e. Unless otherwise agreed, Cu ≤ 0.50%; Ni ≤ 0.30% Cr ≤ 0.30% and Mo ≤ 0.15%,

f. Unless otherwise agreed,

g. Unless otherwise agreed, Nb + V + Ti ≤ 0.15%,

h. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 0.50% Cr ≤ 0.50% and MO ≤ 0.50%,

i. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.50% and MO ≤ 0.50%,

j. B ≤ 0.004%,

k. Unless otherwise agreed, Cu ≤ 0.50% Ni ≤ 1.00% Cr ≤ 0.55% and MO ≤ 0.80%,

l. For all PSL 2 pipe grades except those grades with footnotes j noted, the following applies. Unless otherwise agreed no intentional addition of B is permitted and residual B ≤ 0.001%.

|

Mechanical properties:

|

Pipe Grade

|

Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 1

|

Seam of Welded Pipe

|

|

Yield Strength a

|

Tensile Strength a

|

Elongation

|

Tensile Strength b

|

|

Rt0,5 PSI Min

|

Rm PSI Min

|

(in 2in Af % min)

|

Rm PSI Min

|

|

A

|

30,500

|

48,600

|

c

|

48,600

|

|

B

|

35,500

|

60,200

|

c

|

60,200

|

|

X42

|

42,100

|

60,200

|

c

|

60,200

|

|

X46

|

46,400

|

63,100

|

c

|

63,100

|

|

X52

|

52,200

|

66,700

|

c

|

66,700

|

|

X56

|

56,600

|

71,100

|

c

|

71,100

|

|

X60

|

60,200

|

75,400

|

c

|

75,400

|

|

X65

|

65,300

|

77,500

|

c

|

77,500

|

|

X70

|

70,300

|

82,700

|

c

|

82,700

|

|

a. For intermediate grade, the difference between the specified minimum tensile strength and the specified minimum yield for the pipe body shall be as given for the next higher grade.

|

|

b. For the intermediate grades, the specified minimum tensile strength for the weld seam shall be the same as determined for the body using foot note a.

|

|

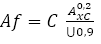

c. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be determined using the following equation:

|

|

|

Where C is 1 940 for calculation using Si units and 625 000 for calculation using USC units

|

|

Axc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches) , as follows

|

|

– For circular cross-section test pieces, 130mm2 (0.20 in2) for 12.7 mm (0.500 in) and 8.9 mm (.350 in) diameter test pieces; and 65 mm2 (0.10 in2) for 6.4 mm (0.250in) diameter test pieces.

|

|

– For full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2)

|

|

– For strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2)

|

|

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch)

|

|

Pipe Grade

|

Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 2

|

Seam of Welded Pipe

|

|

Yield Strength a

|

Tensile Strength a

|

Ratio a,c

|

Elongation

|

Tensile Strength d

|

|

Rt0,5 PSI Min

|

Rm PSI Min

|

R10,5IRm

|

(in 2in)

|

Rm (psi)

|

|

|

|

|

Af %

|

|

|

Minimum

|

Maximum

|

Minimum

|

Maximum

|

Maximum

|

Minimum

|

Minimum

|

|

BR, BN,BQ,BM

|

35,500

|

65,300

|

60,200

|

95,000

|

0.93

|

f

|

60,200

|

|

X42,X42R,X2Q,X42M

|

42,100

|

71,800

|

60,200

|

95,000

|

0.93

|

f

|

60,200

|

|

X46N,X46Q,X46M

|

46,400

|

76,100

|

63,100

|

95,000

|

0.93

|

f

|

63,100

|

|

X52N,X52Q,X52M

|

52,200

|

76,900

|

66,700

|

110,200

|

0.93

|

f

|

66,700

|

|

X56N,X56Q,X56M

|

56,600

|

79,000

|

71,100

|

110,200

|

0.93

|

f

|

71,100

|

|

X60N,X60Q,S60M

|

60,200

|

81,900

|

75,400

|

110,200

|

0.93

|

f

|

75,400

|

|

X65Q,X65M

|

65,300

|

87,000

|

77,600

|

110,200

|

0.93

|

f

|

76,600

|

|

X70Q,X65M

|

70,300

|

92,100

|

82,700

|

110,200

|

0.93

|

f

|

82,700

|

|

X80Q,X80M

|

80,.500

|

102,300

|

90,600

|

119,700

|

0.93

|

f

|

90,600

|

|

a. For intermediate grade, refer to the full API5L specification.

|

|

b. for grades > X90 refer to the full API5L specification.

|

|

c. This limit applies for pies with D> 12.750 in

|

|

d. For intermediate grades, the specified minimum tensile strength for the weld seam shall be the same value as was determined for the pipe body using foot a.

|

|

e. for pipe requiring longitudinal testing, the maximum yield strength shall be ≤ 71,800 psi

|

|

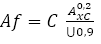

f. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be determined using the following equation:

|

|

|

Where C is 1 940 for calculation using Si units and 625 000 for calculation using USC units

|

|

Axc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches) , as follows

|

|

– For circular cross-section test pieces, 130mm2 (0.20 in2) for 12.7 mm (0.500 in) and 8.9 mm (.350 in) diameter test pieces; and 65 mm2 (0.10 in2) for 6.4 mm (0.250in) diameter test pieces.

|

|

– For full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2)

|

|

– For strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe, rounded to the nearest 10 mm2 (0.10in2)

|

|

U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch

|

|

g. Lower values fo R10,5IRm may be specified by agreement

|

|

h. for grades > x90 refer to the full API5L specification.

|

API 5L Pipe Quality Inspection Standards:

Hydrostatic Test

The pipe shall be subjected to a hydrostatic test with no leakage in the weld or pipe body. If the pipe section used has successfully passed the test, the joint does not need to be hydrostatically tested.

Bend Test

No cracks shall be present in any part of the test piece and no openings shall be present in the weld.

Flattening Test

The acceptance criteria for the flattening test shall be:

EW Pipe D<12.750 inches:

X60, T 500 inches. The weld shall not open until the distance between the plates is less than 66% of the original outside diameter. For all grades and wall thicknesses, it is 50%.

For pipes with D/t > 10, the weld shall not open until the distance between the plates is less than 30% of the original outside diameter.

For other sizes, refer to the complete API 5L specification.

CVN Impact Test for PSL2

Many PSL2 pipe sizes and grades require CVN. Seamless pipe will be tested inside the pipe body. Welded pipe is tested on the pipe body, pipe welds, and heat affected zone. Refer to the full API 5L specification for sizes and grades and a chart of required absorbed energy values.

Read more: Schedule 40 Carbon Steel Pipe or Schedule 80 Carbon Steel Pipe

![]()

![]()