Construcción naval

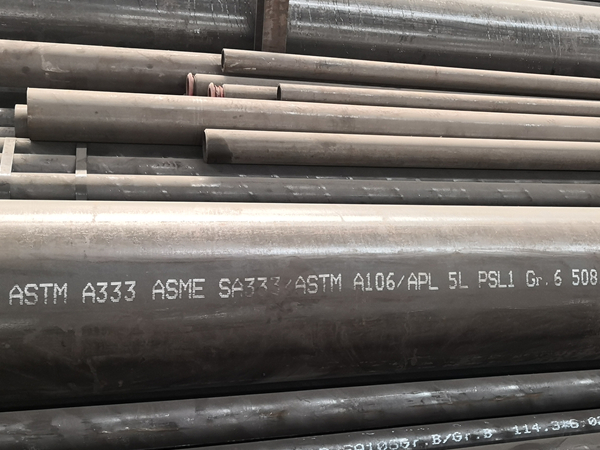

Especificación estándar ASTM A333 para tubería sin costura y tubería soldada para servicio a baja temperatura y otras aplicaciones con dureza de muesca requerida.

Material: Gr.6

Esta especificación cubre las tuberías de acero al carbono y de aleación soldadas y sin soldadura de pared destinadas a su uso a bajas temperaturas. La tubería se fabricará mediante el proceso de soldadura o sin costura sin adición de metal de aporte en la operación de soldadura.

Requisitos químicos de ASTM A333

| Composition, % | |||

| Element | Grade 1 | Grade 3 | Grade 6 |

| Carbon, max | 0.30 | 0.19 | 0.30 |

| Manganese | 0.40 – 1.06 | 0.31 – 0.64 | 0.29 – 1.06 |

| Phosphorous, max | 0.025 | 0.025 | 0.025 |

| Sulfur, max | 0.025 | 0.025 | 0.025 |

| Silicon | 0.18 -0.37 | 0.10 min | |

| Nickel | 3.18 – 3.82 |

|

|

Requisitos de tracción de ASTM A333

El material se ajustará a los requisitos que se prescriben:

| Grade 1 | Grade 3 | Grade 6 | |||||

| psi | MPa | psi | MPa | psi | MPa | ||

| Tensile Strength, min | 55,000 | 380 | 65,000 | 450 | 60,000 | 415 | |

| Yield Strength, min | 30,000 | 205 | 35,000 | 240 | 35,000 | 240 | |

| Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | ||

| Basic minimum elongation for walls 5/16 in. [8 mm] and over in thickness, strip tests, and for all small sizes tested in full section | 35 | 35 | 30 | 20 | 30 | 16.5 | |

| When the standard round 2-in. or 50-mm gage length or proportionally smaller size test specimen with the gage length equal to 4D (4 times the diameter) is used | 28 | 20 | 22 | 14 | 22 | 12 | |

| For strip tests, a deduction for each 1/32in. [0.8 mm] decrease in wall thickness below 5/16 in. [8 mm] from the basic minimum elongation of the following percentage | 1.75 | 1.25 | 1.50 | 1.00 | 1.50 | 1.00 | |

| Wall Thickness | Grade 1 | Grade 3 | Grade 6 | ||||

| in. | mm | Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse |

| 5/16 (0.312) | 8 | 35 | 25 | 30 | 20 | 30 | 16 |

| 9/32 (.281) | 7.2 | 33 | 24 | 28 | 19 | 28 | 15 |

| 1/4 (.250) | 6.4 | 32 | 23 | 27 | 18 | 27 | 15 |

| 7/32 (.219) | 5.6 | 30 | - | 26 | - | 26 | - |

| 3/16 (.188) | 4.8 | 28 | - | 24 | - | 24 | - |

| 5/32 (.156) | 4 | 26 | - | 22 | - | 22 | - |

| 1/8 (.125) | 3.2 | 25 | - | 21 | - | 21 | - |

| 3/32 (.094) | 2.4 | 23 | - | 20 | - | 20 | - |

| 1/16 (.063) | 1.6 | 21 | - | 18 | - | 18 |

-

|