Husteel Industry Group has quality control sytem including all production process starting from raw material and continuing welding wire and flux till to transportation.Quality management is one of the most important function that all required tests and inspections are carried out in compliance with the customer requirements and related standards by using modern inspection and testing equipments.The tests are guaranteed through test conducted by using modern measurement and equipments, the calibration of these equipments performed periodically by the acrredited corporations.

1. Visual and Dimensional Check

1. Visual and Dimensional Check

Water Leakage Test --Hydrostatic Tests

Non-destructive Tests

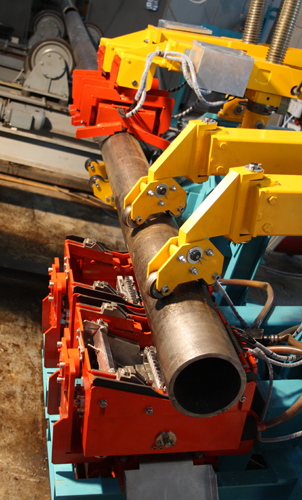

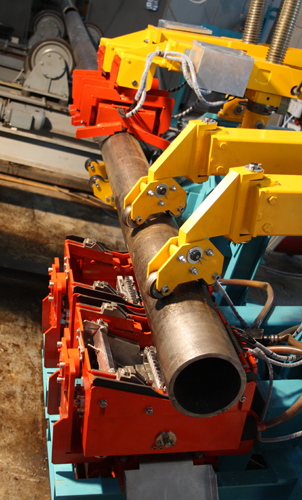

.Automatic Ultrasonic Weld Inspection

.Automatic Ultrasonic Body Lamination Inspection

.Manual Ultrasonic Inspection

.Real Time Radiographic Inspection

.Liquid Penetrant Inspection

.Magnetic Particle Inspection

.Magnetic Field Measurement

Destructive Tests

.Tensile Test

.Chemical Analysis

.Guided Bending Test

.Charpy V Notch Impact Test

.Hardness Test

.Drop Weight Tear Test (DWTT)

.Micro Anaysis

.Macro Analysis

2. Raw Materail Supply

Raw material is supplied only directly from approved HRC producers. Mill Test Certificates showing full mechanical and chemical properties should 100% conform the tests applied at the final receipt of materials on our own labs.

3. Coil Preparation

HRC Coils that will be used for production is selected from coil list which approved by Quality department. The coil list can be performed via either electronic media or a written report. The identification of coil is checked corresponding with coil label and coil list.The heat and coil number of selected coil is be recorded to the pipe production report that showing related pipe number.

Following steps are taken during test and inspection of Raw material

.Documentation Control,

.Unloading Visual-Identification Check,

.Storage Criteria,

.Verification of Physical and Chemical Properties,

.Releasing Process,

.Quarantine Process,

.Returning Back/Rejecting The Material.