-

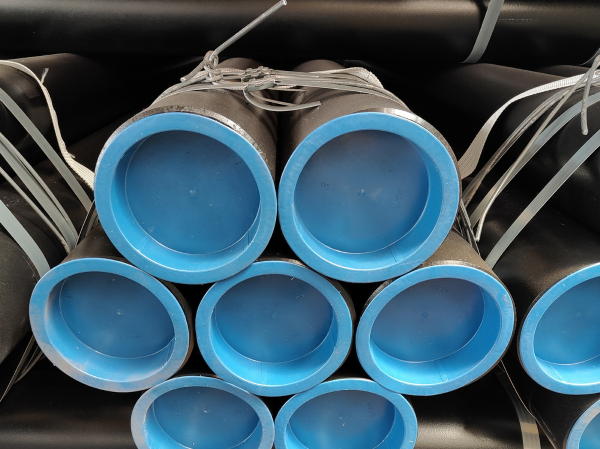

what does sch 40 seamless pipe mean?sch 40 seamless pipe refers to a specific type of steel pipe with a wall thickness of 40, which has no seams or welds during its manufacturing process. "sch 40" means standard wall thickness, and this type of pipe is usually used in applications that require mediu

-

astm a500 - standard specification for cold-formed welded and seamless carbon steel structural tubing in round tube, square tube and rectangular tube shapes.astm a500 is a standard developed by the american society for testing and materials (astm) specifically for cold-formed welded and seamless car

-

what is a rectangular tube ?rectangular tube, also known as rectangular hollow section (rhs) or structural hollow section, is a hollow steel with a rectangular cross section, which belongs to a type of welded steel pipe or cold-formed steel. it is the same "hollow profile" as square tube (shs

-

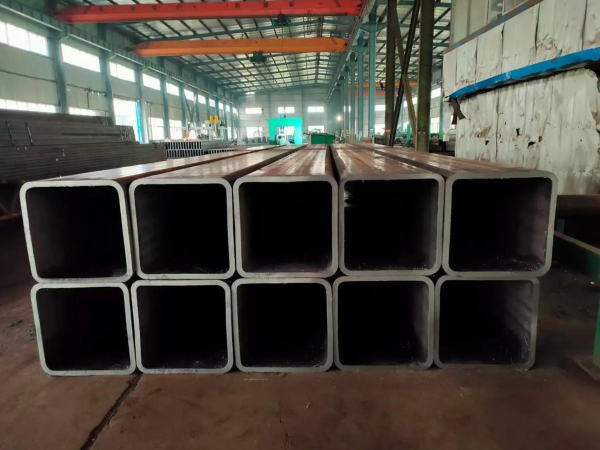

what is a square tube?square tube, also known as square hollow section (shs) or structural hollow section, is a metal tubular material with a square cross section, which is widely used in construction, machinery manufacturing, steel structure and other fields. square tubes are usually

-

what is oil casing pipe?oil casing pipe is a key pipe used in oil and gas drilling projects to reinforce the wellbore of oil and gas wells, isolate the formation, and protect the integrity of the wellbore. it constitutes the main body of the well structure and directly affects the safety, production