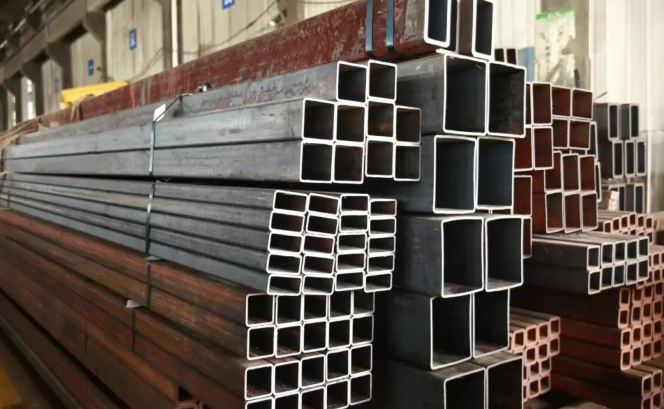

What is a rectangular tube ?

Rectangular tube, also known as

Rectangular Hollow Section (RHS) or

Structural Hollow Section, is a hollow steel with a rectangular cross section, which belongs to a type of welded steel pipe or cold-formed steel. It is the same "hollow profile" as

square tube (SHS), but the length and width are not equal (such as 50×30mm).

Rectangular tube is mainly used in the manufacture of structural parts, tools and mechanical parts. Its cross section is rectangular, which belongs to the branch type of special-shaped seamless steel pipe. Compared with round tube, it has a larger moment of inertia and section modulus, which can improve the bending and torsion resistance, while reducing the weight of the structure and saving steel.

Classification of rectangular tubes:

According to the production process: It can be divided into seamless rectangular tubes (no weld, higher strength) and welded rectangular tubes (with welds). Among them, seamless rectangular tubes are formed by different processes such as hot rolling, cold drawing, extrusion, etc.; welded rectangular tubes include arc welding (SAW), high frequency welding (HFW) and other processes.

By material: divided into ordinary carbon steel rectangular tube, stainless steel rectangular tube, low alloy steel rectangular tube, etc.

By use: divided into decorative rectangular tube, structural rectangular tube, mechanical rectangular tube, architectural rectangular tube, etc.

By surface treatment: galvanized rectangular tube, spray-painted rectangular tube, black rectangular tube (uncoated), polished.

Characteristics of rectangular tube:

1. Structural advantages: strong bending resistance in the long side direction (large moment of inertia), suitable for unidirectional force structures (such as beams, guide rails).

2. Lightweight: hollow design reduces weight by 30%-50% compared to solid steel, reducing transportation and installation costs.

3. Convenient connection: large flat contact area, easy to weld, bolt or assemble fixtures.

4. Diverse surface treatment: galvanized, spray-painted, polished, to meet different environmental requirements.

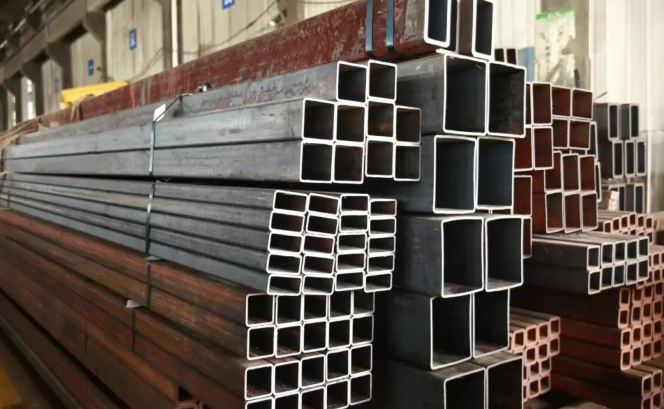

Common rectangular tube sizes:

Length × width: 10 × 5mm ~ 500 × 300mm

Wall thickness: 0.5 ~ 25mm

Length: usually 6m, can be customized to 12m.

Note: The wall thickness tolerance of cold-formed steel is usually ±0.2mm, and the tolerance of hot-rolled tubes is slightly larger (±0.5mm). When selecting, it is necessary to combine load calculation to avoid cost waste caused by over-design.

Implementation standards:

ASTM A500: Carbon steel rectangular tube for structure (divided into Gr.A/B/C/D grades)

EN 10210-2: Hot-formed hollow profiles (material S235-S460)

JIS G 3463: Welded rectangular tube for building structure

ISO 657-1: Dimensions and tolerances of hot-rolled steel rectangular tubes

Manufacturing process of rectangular tubes:

Depending on different manufacturing processes, rectangular tubes can be divided into welded rectangular tubes and seamless rectangular tubes.

(1) Welded rectangular tube (mainstream process)

Raw material preparation: unwinding and leveling of steel strip

Cold bending: gradually bending into a rectangle through multiple sets of rollers (direct forming or first round and then square)

High frequency welding: using high frequency current to fuse the weld (HFW/

ERW)

Sizing and straightening: adjusting the size and eliminating stress

Surface treatment: galvanizing, painting or polishing

(2) Seamless rectangular tube (high-demand scenario)

Process: round tube billet → hot perforation → cold drawing/cold rolling into rectangle → annealing

Features: no weld, high strength, but the cost increases by 3-5 times

(3) Special process

Hot-dip galvanizing: immersing in zinc liquid (zinc layer ≥ 60μm), used for outdoor corrosion protection

Plastic spraying: electrostatic spraying of PE/PVC coating, beautiful and weather-resistant

Core advantages of rectangular tube:

1. Excellent mechanical properties: the bending strength in the long side direction is 20%-30% higher than that of square tube (under the same cross-sectional area)

2. Good economy: The cost of welded rectangular tube is more than 50% lower than that of seamless rectangular tube, which is suitable for mass production.

3. Convenient construction: It can be cut and drilled on site, and is highly compatible with H-shaped steel/C-shaped steel and other profiles.

4. Environmentally friendly and recyclable: 100% recyclable, in line with green building standards.

Typical application areas of rectangular tubes:

1. Buildings and infrastructure

Rectangular tubes are often used in columns, beams and bridge support structures of steel structure buildings, such as high-rise building frames, subway platform canopies, stadium stand roofs, etc. Its flat surface is convenient for installing glass curtain walls or metal sheets, and the connection parts are firm, which can effectively resist the torsion caused by wind loads.

2. Machinery manufacturing and industrial equipment

The conveyor frame of the automated production line, the arm structure of engineering machinery (such as excavators, cranes) and the frame of textile machinery mostly use rectangular tubes. Stainless steel rectangular tubes are often used in food processing equipment, pharmaceutical machinery and other precision instruments due to their corrosion resistance.

3. Automobile manufacturing

Rectangular tubes also play an important role in automobile manufacturing, such as frames, exhaust pipes, fuel pipes, etc. The light weight, high strength and good corrosion resistance of rectangular tubes make automobiles safer, energy-saving and environmentally friendly.

4. Transportation

Rectangular tubes are used in high-speed rail carriage chassis, subway vehicle side wall frames and commercial vehicle beams. Aluminum alloy rectangular tubes reduce the weight of the vehicle body while ensuring impact resistance, and are suitable for the manufacture of high-speed rail, subway and other transportation vehicles.

5. Home decoration

Such as customized shelves and stair handrails, the surface can be galvanized or sprayed to enhance the aesthetics.

6. Other fields

Rectangular tubes are also used for street light poles, traffic sign poles and integrated pipe corridor cable brackets in municipal engineering. The internal space can be layered to arrange pipelines to improve the utilization rate of underground space.

Rectangular tube (RHS) vs Square tube (SHS): Key difference

Rectangular tube: unequal length and width, stronger unidirectional bending resistance. Rectangular tubes are 5%-10% more expensive than square tubes and are often used for beams, rails, and unidirectional force-bearing frames.

Square tubes: equal length and width, isotropic. Square tubes are cheaper and are often used for columns and symmetrical structural parts.

Comparison between rectangular tubes and round tubes and suggestions for special scenarios:

In scenarios that require multi-dimensional force or compact space (such as stereo garage frames), rectangular steel tubes are better;

Due to their isotropic characteristics, round tubes are more suitable for fluid transportation or high-pressure pipelines. For example, wind power towers need to withstand 360° wind pressure, so round tubes are preferred.

Read more: Characteristics and Applications of Square Structural Tubing