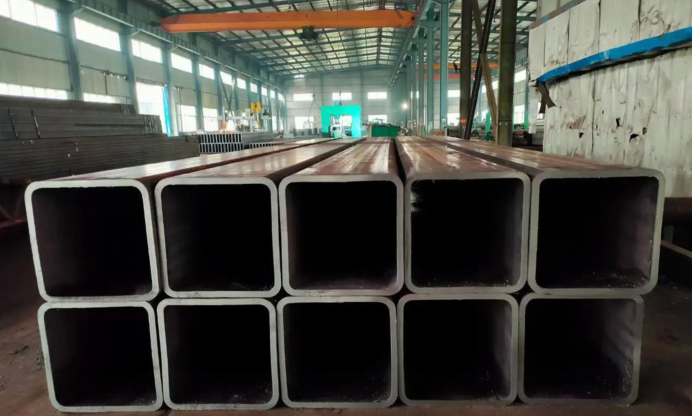

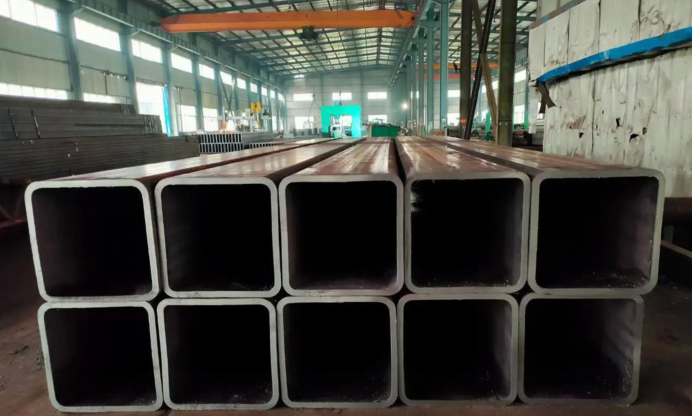

What is a square tube?

Square tube, also known as

Square Hollow Section (SHS) or

Structural Hollow Section, is a metal tubular material with a square cross section, which is widely used in construction, machinery manufacturing, steel structure and other fields. Square tubes are usually made of carbon steel, stainless steel or aluminum alloy, and have different sizes and thicknesses to meet specific structural requirements.

Classification of square tubes:

By production process: seamless square tube (no weld, higher strength) and welded square tube (with weld), among which welded square tube has lower cost and seamless square tube has stronger pressure bearing capacity.

By material: carbon steel square tube, stainless steel square tube, alloy steel square tube, etc.

By use: structural square tube, decorative square tube, building square tube, etc.

By surface treatment: galvanized square tube, painted square tube, black tube (no coating).

Main features of square tube:

1. Light structure but high strength: hollow design reduces weight while maintaining bending and torsion resistance.

2. Easy to process: can be cut, welded, drilled, and adapted to a variety of installation needs.

3. Corrosion resistance: galvanized or stainless steel square tubes are suitable for humid or corrosive environments.

4. Aesthetics: The appearance is neat and suitable for exposed occasions (such as decoration, railings).

Common square tube sizes:

Side length range: usually 10×10mm to 500×500mm, special sizes can be customized.

Wall thickness range: 0.5mm to 20mm, common thicknesses are 1.0mm, 1.5mm, 2.0mm, 3.0mm, etc.

Length: The standard length is 6 meters, which can also be customized according to needs.

1) Side length selection

Small size (10×10~50×50mm): furniture, decoration, light bracket.

Medium size (60×60~150×150mm): building steel structure, mechanical frame.

Large size (200×200mm and above): heavy factory building, bridge support.

2) Wall thickness selection

1.0~1.5mm: suitable for light load, decoration/non-load-bearing structure, such as display racks, home furnishings.

2.0~3.0mm: suitable for medium load, general structural tube, such as stair handrails, equipment brackets.

4.0~6.0mm: heavy load, suitable for load-bearing frames, such as factory beams, heavy machinery bases.

Square tube manufacturing process:

According to different manufacturing processes, square tubes can be divided into

seamless square tubes and

welded square tubes.

Seamless square tubes are produced by

seamless pipe (smls) production lines, that is, the blanks are forged into finished pipes by stretching and expanding, and the seamless round tubes are extruded into square shapes. They have high strength and precision and are widely used in high-end fields such as petroleum and chemical industry.

Welded square tubes are pipes made by processes such as rolling, forming, and welding. The production cost is low (30%~50% cheaper than seamless pipes) and they are widely used in construction, machinery and other fields.

Square tube standards:

1. General structural square steel tube

ASTM A500: Structural Steel Hollow Sections

ASTM A1085: High-Strength Hollow Sections

2. Cold-formed welded square steel tube

ASTM A513: Electric-Resistance Welded Pipe

3. Stainless steel square steel tube

ASTM A312: Seamless Stainless Steel Pipe

ASTM A554: Welded Stainless Steel Tube

4. Special performance square steel tube

ASTM A847: Weathering Steel Hollow Sections

ASTM A1065: Cold-Formed Welded High-Strength

The core advantages of square tubes:

1. Save materials: Compared with solid steel, it is light and has lower cost.

2. Convenient construction: easy to transport and install, reducing construction period.

3. Versatility: suitable for load-bearing structures and decorative purposes.

4. Environmental protection: recyclable and in line with sustainable development requirements.

Application areas of square tubes:

1. Construction engineering

Square tubes are widely used in the construction field, such as steel structure frames, bridges, highway guardrails, etc. Square tubes have become an important supporting material for modern buildings with their high strength, light weight and beautiful appearance.

- Steel structure frame: Square tubes are often used in the supporting structures of large-span buildings such as factories and gymnasiums. For example, the "Ice Ribbon" of the Beijing Winter Olympics Speed Skating Hall uses high-strength square tube welded grids.

- Decoration: Stainless steel square tubes are widely used in stair handrails, curtain wall frames, etc. due to their corrosion resistance.

2. Machinery manufacturing

In machinery manufacturing, square tubes are often used to make various mechanical parts, such as shafts, gears, brackets, etc. Its excellent mechanical properties and machinability make square tubes have a wide range of application prospects in the field of machinery.

- As the base material of equipment frames and conveyor rollers, such as conveyor belt brackets in automated production lines, 40mm×40mm×2mm square tubes are commonly used.

3. Automobile manufacturing

Square tubes also play an important role in automobile manufacturing, such as frames, exhaust pipes, fuel pipes, etc. The light weight, high strength and good corrosion resistance of square tubes make cars safer, energy-saving and environmentally friendly.

- Automobile chassis reinforcements, high-speed rail carriage frames, etc. all use high-strength square tubes. The battery pack bracket of a certain brand of new energy vehicle models uses aluminum alloy square tubes, which reduces weight by 30.

4. Other fields

- Agricultural greenhouses: Galvanized square tubes are rust-proof and durable, and are the mainstream skeleton material for greenhouses.

- Furniture manufacturing: Many racks of brands such as IKEA use thin-walled square tubes, which take into account both beauty and load-bearing.

Key points for quality inspection of square tubes:

Dimensional tolerance: Check whether the side length and wall thickness meet the standards.

Weld quality (welded tube): No cracks, incomplete penetration and other defects (ultrasonic flaw detection).

Surface defects: No rust, pits, or galvanized layer shedding.

Mechanical properties: Sampling test of tensile strength and yield strength (manufacturer required to provide test report).

Notes on square tube selection:

Material selection: Galvanized or stainless steel is preferred for outdoor environments; carbon steel thick-walled tubes are required for load-bearing structures.

Dimension matching: Calculate the side length and wall thickness according to the load to avoid over-design or insufficient strength.

Standard certification: Ensure compliance with industry standards such as American Standards (ASTM).

Applicable principles:

Prioritize square tubes: when lightweight load-bearing, rapid construction or complex structural design is required.

Careful selection of square tubes: Extreme high pressure/high temperature environment (seamless thick-walled tubes or special alloys are required).

Tips for cost control of square tubes:

Non-load-bearing parts: welded square tubes are preferred, which are 30% to 50% cheaper than seamless tubes.

Indoor use: black tubes + self-spray paint to save galvanizing costs.

Bulk purchase: standard sizes (such as 50×50×2.0mm) are more economical than customized specifications.