API 5L ERW line pipe is a high-frequency electric resistance welded (ERW) steel pipe produced according to the API 5L standard of the American Petroleum Institute (API), which is specially used for land and submarine pipeline transportation systems of energy media such as oil and natural gas.

Core features:

Adopting ERW (Electric Resistance Welding) welding process, high production efficiency and low cost.

Must meet the strict specifications of API 5L for materials, dimensions, mechanical properties and testing.

API 5L ERW Line Pipe Standard and Grade:

| Grade A Carbon Steel |

(ASTM A53, A523, API 5L PSL1 ) |

|---|---|

| Minimum Yield Strength: | 30,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 48,000 psi |

|

Notes: This grade may be used for standard pipe, line pipe, or conduit pipeas specified in the various ASTM and API specifications. |

|

| Grade B Carbon Steel |

(ASTM A53, A523, API 5L PSL1) |

API 5L PSL2 |

|---|---|---|

| Minimum Yield Strength: | 35,000 psi | 35,000 psi |

| Maximum Yield Strength: | None | 65,000 psi |

| Minimum Tensile Strength: | 60,000 psi | 60,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This grade may be used for standard pipe, line pipe, or conduit pipeas specified in the various ASTM and API specifications. |

||

| API 5L X42 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 42,000 psi | 42,000 psi |

| Maximum Yield Strength: | None | 72,000 psi |

| Minimum Tensile Strength: | 60,000 psi | 60,000 psi |

| Maximum Tensile Strength | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X46 | PSL1 | PSL 2 |

|---|---|---|

| Minimum Yield Strength: | 46,000 psi | 46,000 psi |

| Maximum Yield Strength: | None | 76,000 psi |

| Minimum Tensile Strength: | 63,000 psi | 63,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X52 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 52,000 psi | 52,000 psi |

| Maximum Yield Strength: | None | 77,000 psi |

| Minimum Tensile Strength: | 66,000 psi | 66,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X56 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 56,000 psi | 56,000 psi |

| Maximum Yield Strength: | None | 79,000 psi |

| Minimum Tensile Strength: | 71,000 psi | 71,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X60 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 60,000 psi | 60,000 psi |

| Maximum Yield Strength: | None | 82,000 psi |

| Minimum Tensile Strength: | 75,000 psi | 75,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X65 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 65,000 psi | 65,000 psi |

| Maximum Yield Strength: | None | 87,000 psi |

| Minimum Tensile Strength: | 77,000 psi | 77,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| API 5L X70 | PSL1 | PSL2 |

|---|---|---|

| Minimum Yield Strength: | 70,000 psi | 70,000 psi |

| Maximum Yield Strength: | None | 90,000 psi |

| Minimum Tensile Strength: | 82,000 psi | 82,000 psi |

| Maximum Tensile Strength: | None | 110,000 psi |

|

Notes: This is a standard line pipe grade specifiedin API (American Petroleum Institute) specification 5L. |

||

| Grade 1 Carbon Steel | (ASTM A252) |

|---|---|

| Minimum Yield Strength: | 30,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 50,000 psi |

|

Notes: This grade is a standard grade for ASTM A252. The specification coversthe requirements for welded and seamless steel piling pipe. |

|

| Grade 2 Carbon Steel | (ASTM A252) |

|---|---|

| Minimum Yield Strength: | 35,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 60,000 psi |

|

Notes: This grade is a standard grade for ASTM A252. The specification coversthe requirements for welded and seamless steel piling pipe. |

|

| Grade 3 Carbon Steel | (ASTM A252) |

|---|---|

| Minimum Yield Strength: | 45,000 psi |

| Maximum Yield Strength: | None |

| Minimum Tensile Strength: | 66,000 psi |

|

Notes: This grade is a standard grade for ASTM A252. The specification coversthe requirements for welded and seamless steel piling pipe. |

|

Features and Advantages of Husteel Group Products ERW Line Pipe:

Clients prefer our carbon steel ERW welded pipe products for the following reasons:

1. Smooth Surface

Our hot rolled strip is continuously cold formed to produce smooth surface and uniform wall thickness pipes with excellent coating performance and flow characteristics.

2. Stronger and lighter pipe wall

Husteel uses high-strength, thinner steel strips, which are welded into high-toughness steel pipes by high-frequency resistance welding machines to meet strict tolerance and strength specifications.

3. Uniform size and quality

Our ERW steel pipe products are made of hot rolled steel strips with uniform wall thickness. Husteel's highly automated process, combined with continuous non-destructive testing, visual inspection and hydrostatic pressure testing, ensures that our customers receive the highest quality steel pipe products.

4. Cost advantage

The price of our ERW steel pipe is only 60-70% of that of seamless pipe and 80% of that of LSAW pipe, and the raw material utilization rate is >98% (only 85% for seamless pipe).

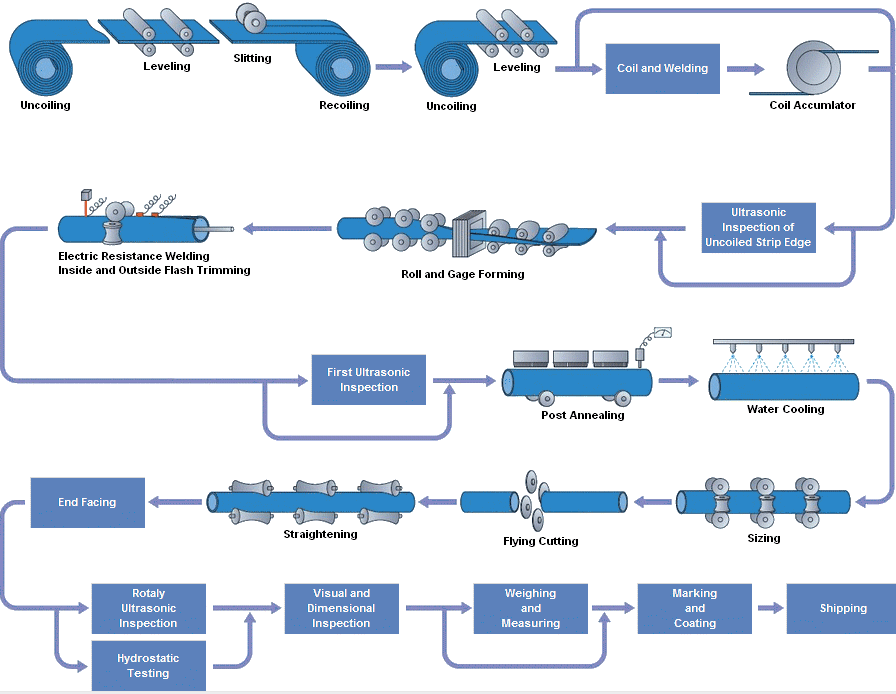

ERW Line Pipe Manufacturing Process:

Typical applications of API 5L ERW line pipe:

1. Onshore oil and gas gathering and transportation: low-pressure/medium-pressure pipelines from wellhead to processing plant (Gr.B/X52).

2. Urban gas pipeline network: medium-pressure transmission pipelines of DN200~DN400 (X42/X60).

3. Refinery pipelines: transportation of crude oil and finished oil (internal anti-corrosion coating required).

4. Structural pipes: auxiliary supports of offshore platforms (need galvanizing or anti-corrosion treatment).

Scenarios where ERW is not recommended:

1. Sour oil and gas fields (H₂S partial pressure > 0.3kPa requires special certification)

2. Deep-sea pipelines (thick-wall LSAW or seamless pipes are required)

3. Ultra-high pressure steam (> 25MPa)

FAQ:

Q1: Can API 5L ERW pipe replace seamless pipe?

→ Yes, but must meet the following requirements:

Pressure ≤ 25MPa and pass strict non-destructive testing.

Additional HIC/SSC testing is required for sour environments.

Q2: How to distinguish ERW from seamless API 5L pipes?

→ Seamless pipes are marked with "S" (such as API 5L X42 S), while ERW pipes do not have this mark.

Q3: What is the biggest disadvantage of ERW pipes?

→ The weld area may become the starting point of brittle fracture under extreme conditions (such as low temperature of -45℃).

Q4: What is the maximum pressure limit of ERW pipes?

→ Usually ≤25MPa (X52 PSL2), seamless pipe or LSAW is required for higher pressure.

Conclusion:

API 5L ERW line pipe has become the first choice for onshore pipelines below DN600 with its core advantages of high efficiency, low cost, reliable welding quality and lightweight. Note when selecting:

ERW is preferred for pressure ≤25MPa, and composite pipe design is considered for higher pressure.

Corrosive environment requires 3PE coating or galvanizing.

Suppliers are required to provide API 5L PSL2 certification + UT test report.

Read more: API 5L Seamless Line Pipe or ASTM A53 GR.B ERW Pipe