API Tubing and Casing sizes are standardized under API SPEC 5CT, which defines various dimensions for both steel casing and tubing used in oil and gas wells. OCTG casing pipe sizes range from 4 1/2" to 20" in diameter, while tubing sizes typically range from 1.05" to 4 1/2".

Husteel Industry Group offers a full range of API steel casing and tubing to meet the various needs of oil exploration and production. The following are OCTG casing and tubing dimensions & weight charts, continue reading to learn more.

Common API steel grades: H40, J55, K55, N80, L80, C90, T95, P110, etc.

Contact us Email: info@husteel-group.com

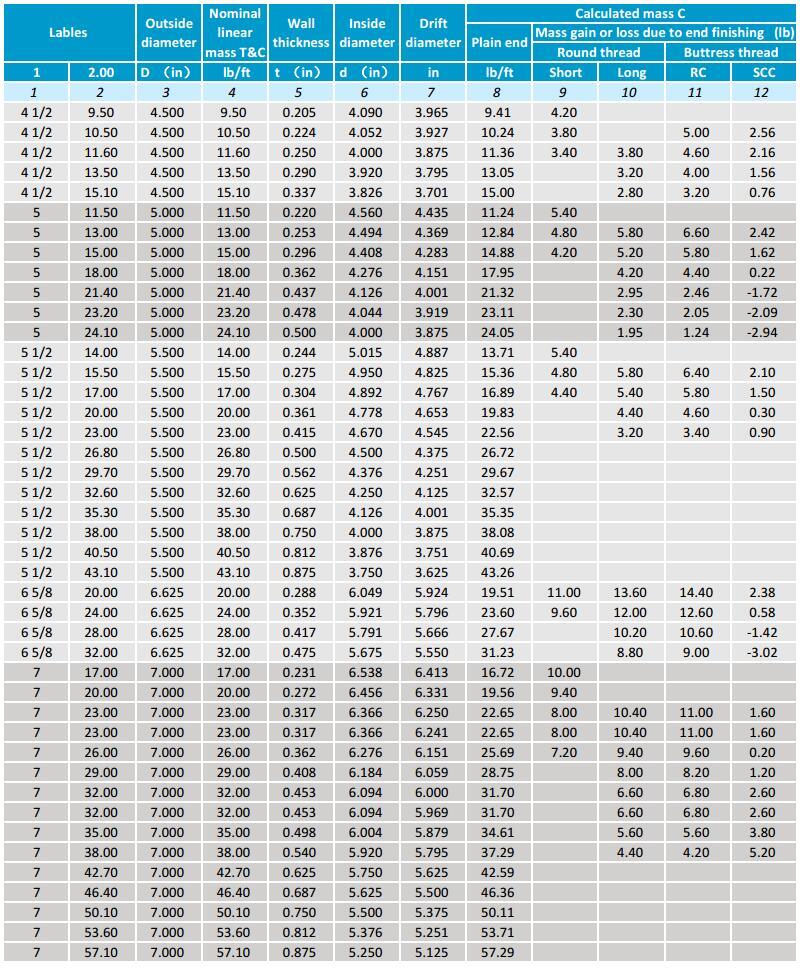

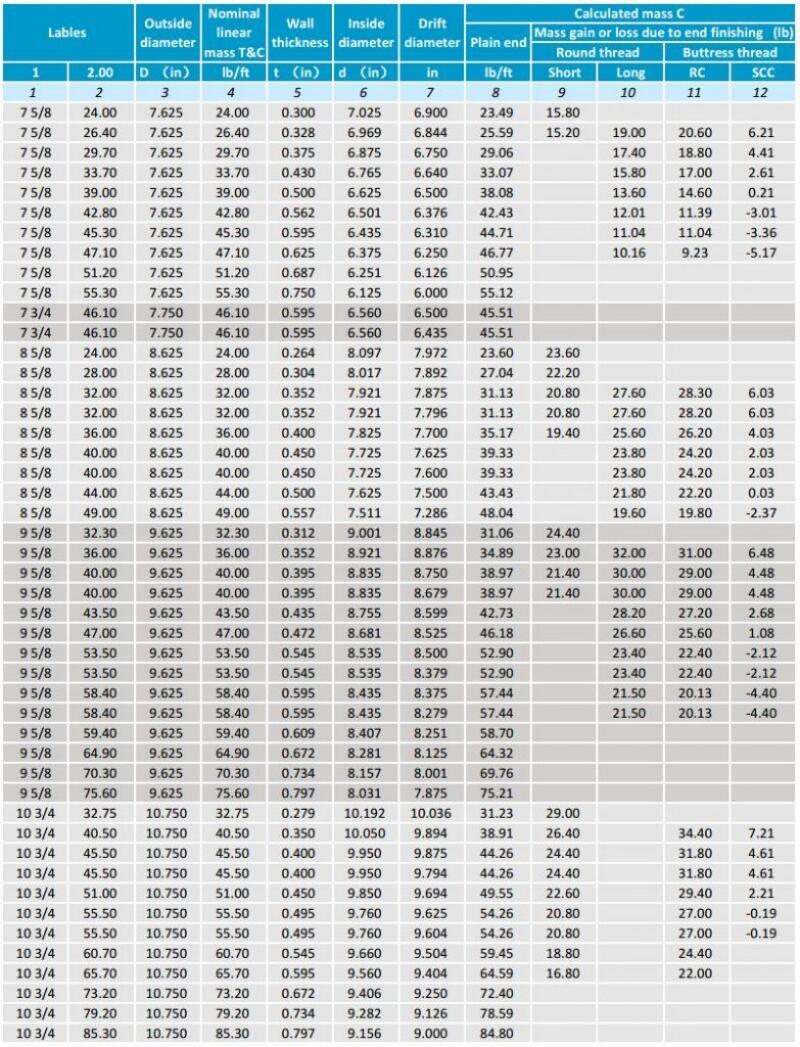

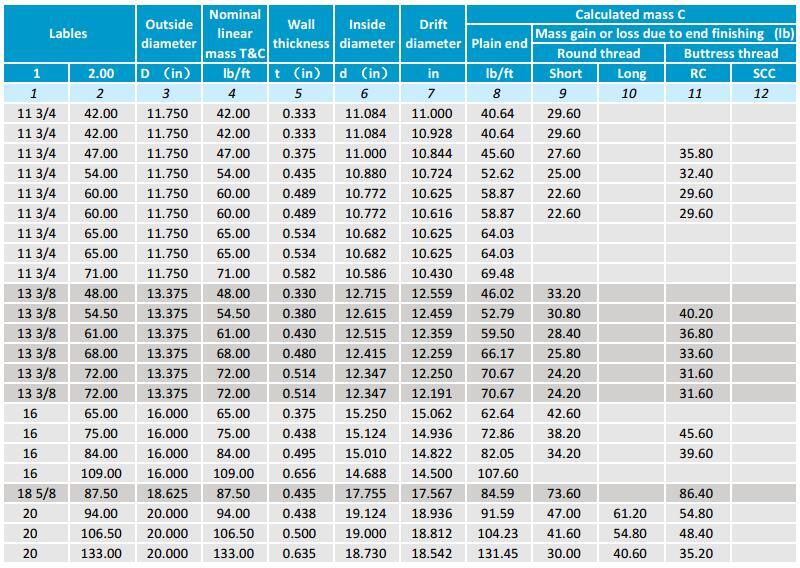

OCTG Steel Casing Pipe Dimensions and Weight Chart:

Common API steel grades for steel casing:

H40, J55, K55, N80, L80, P110, Q125, etc. Different steel grades correspond to different mechanical properties (such as tensile strength and collapse strength).

Common sizes of casing include: 4½", 5", 5½", 6⅝", 7", 7⅝", 8⅝", 9⅝", 10¾", 11¾", 13⅜", 16", 18⅝", 20", etc.

Common wall thickness series: such as 5.21 mm, 6.35 mm, 7.72 mm, 9.17 mm, 10.36 mm, etc.

Large diameter casing: more than 20 inches (such as 24", 30", etc.), usually used for surface casing or special well conditions.

Thread type: including short thread (STC), long thread (LTC), partial trapezoidal thread (BTC), etc., which affect the size of the connection part.

Application scenarios:

Surface casing: large diameter (such as 20" and above), used in shallow layers.

Technical casing: medium size (such as 9⅝"~13⅜"), used in the middle well section.

Production casing: smaller size (such as 4½"~7"), used in oil and gas production layers.

Notes:

Non-API standard casing (such as special materials or sizes) may exceed the above range and need to be customized according to specific needs.

When selecting, it is necessary to combine the well depth, pressure, corrosion environment and other factors for comprehensive design.

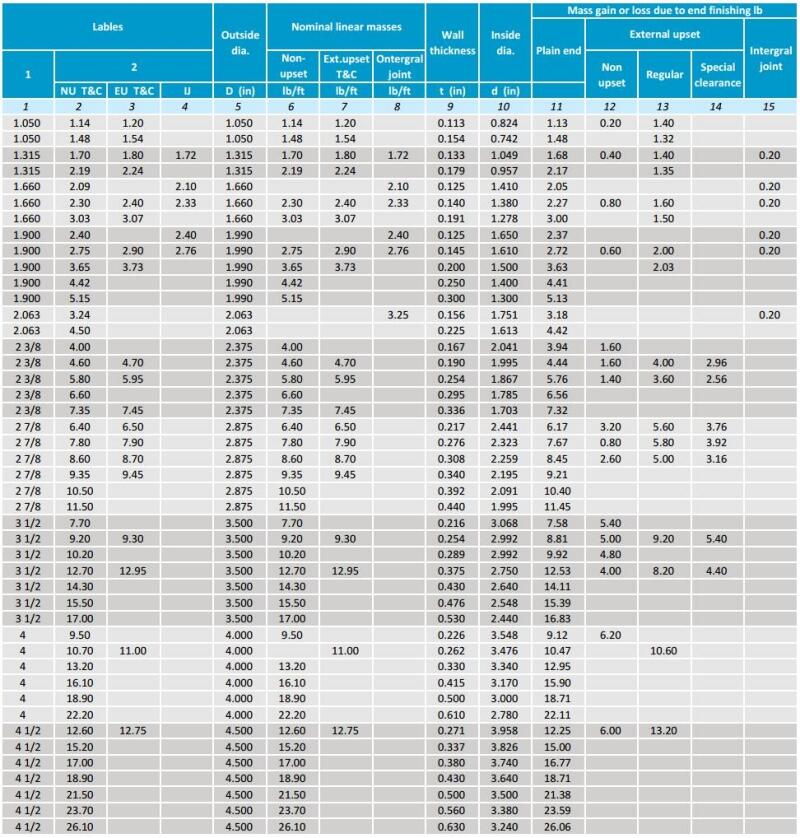

OCTG Tubing Pipe Dimensions and Weight Chart:

Common API steel grades for tubing pipes:

H40, J55, K55, N80, L80, C90, T95, P110, etc.

Different steel grades correspond to different tensile, compressive and corrosion resistance (such as L80 is suitable for hydrogen sulfide environments).

Conventional tubing pipe outer diameter: 1.050 inches (26.7 mm) to 4.500 inches (114.3 mm).

Common sizes (inches/mm):

1.050" (26.7 mm), 1.315" (33.4 mm), 1.660" (42.2 mm), 1.900" (48.3 mm), 2.375" (60.3 mm), 2.875" (73.0 mm), 3.500" (88.9 mm), 4.000" (101.6 mm), 4.500" (114.3 mm).

Special requirements: Non-API standard tubing may exceed this range (such as larger diameter or thin wall design).

Wall thickness range: 0.083 inches (2.11 mm) to 0.400 inches (10.16 mm), depending on steel grade and pressure requirements.

Common wall thickness series:

For example, the wall thickness of 2-7/8" tubing pipe can be: 0.217" (5.51 mm), 0.276" (7.01 mm), 0.308" (7.82 mm), etc.

Single length:

R1: 18~22 feet (5.49~6.71 m)

R2: 27~30 feet (8.23~9.14 m)

R3: 38~42 feet (11.58~12.80 m)

Thread type:

Usually use API round thread (NU) or partial trapezoidal thread (EU), some high-pressure wells use special threads (such as VAM, TMK, etc.).

Application scenarios:

Small size oil pipe (1.050"~2.375"): used for low-pressure or low-yield wells.

Medium-sized tubing (2.875"~3.500"): most common, suitable for conventional production wells.

Large-sized tubing (4.000"~4.500"): used for high-yield wells or water/gas injection wells.

Special wall thickness design:

Thin-wall tubing: used for low-pressure or low-density fluids (such as gas wells), the wall thickness can be as low as 2.11 mm (0.083").

Thick-wall tubing: used for high-pressure, deep wells or corrosive fluids, the wall thickness can reach 16 mm (0.635") or more (customization required).

Notes:

The selection of tubing requires comprehensive consideration of factors such as well depth, pressure, fluid properties (corrosiveness), and temperature.

Non-API standards (such as high alloy materials, special threads) require customized design.

Mechanical properties:

|

Standard |

Grade |

Tensile Strength(MPa) |

Yield Strength(MPa) |

|

API SPEC 5CT |

J55 |

≥517 |

379~552 |

|

K55 |

≥517 |

≥655 |

|

|

N80 |

≥689 |

552~758 |

|

|

L80(13Cr) |

≥655 |

552~655 |

|

|

P110 |

≥862 |

758~965 |

Chemical Composition:

|

Standard |

Grade |

Chemical Composition(%) |

||||||||||

|

C |

Si |

Mn |

P |

S |

Cr |

Ni |

Cu |

Mo |

V |

Als |

||

|

API SPEC 5CT |

J55K55 (37Mn5) |

0.34~0.39 |

0.20~0.35 |

1.25~1.50 |

≤0.020 |

≤0.015 |

≤0.15 |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

N80 (36 Mn2V) |

0.34~0.38 |

0.20~0.35 |

1.45~1.70 |

≤0.020 |

≤0.015 |

≤0.15 |

/ |

/ |

/ |

0.11~0.16 |

≤0.020 |

|

|

L80(13Cr) |

0.15~0.22 |

≤1.00 |

0.25~1.00 |

≤0.020 |

≤0.010 |

12.0~14.0 |

≤0.20 |

≤0.20 |

/ |

/ |

≤0.020 |

|

|

P110 (30CrMo) |

0.26~0.35 |

0.17~0.37 |

0.40~0.70 |

≤0.020 |

≤0.010 |

0.80~1.10 |

≤0.20 |

≤0.20 |

0.15~0.25 |

≤0.08 |

≤0.020 |

|

OCTG Casing and Tubing Meaning:

OCTG stands for Oil Country Tubular Goods and covers a range of pipe products that are critical to oil and gas production, especially drilling operations. These products meet API or similar industry standards and include drill pipe, steel casing, tubing, pup joints, connections and accessories for use in the onshore and offshore oil industry.

Main types and applications of OCTG pipes

1. Casing pipe: Provide structural support in the borehole, prevent wellbore collapse, and isolate different formations. Casing usually uses large diameter pipes, meets standards such as API 5CT, and has different steel grades and thread types.

2. Drill pipe: used to transmit power, rotate the drill bit and circulate drilling fluid during drilling. Drill pipe needs to withstand axial tension, high torque and internal pressure.

3. Tubing pipe: Used to transport oil or natural gas from the formation to the ground. Tubing needs to withstand the pressure during production and resist loads and deformation. Common tubing specifications also meet API 5CT standards and have a variety of diameters and connection types.