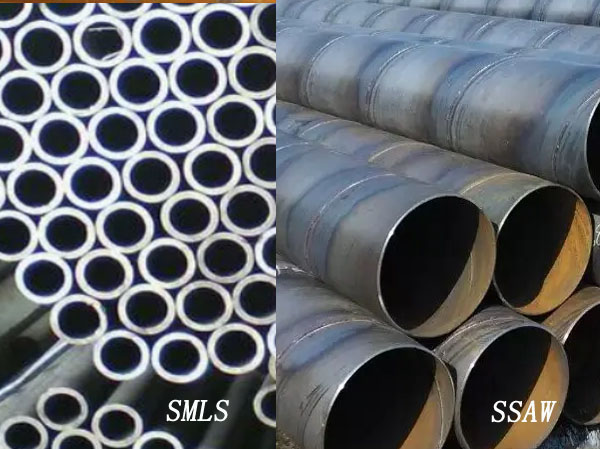

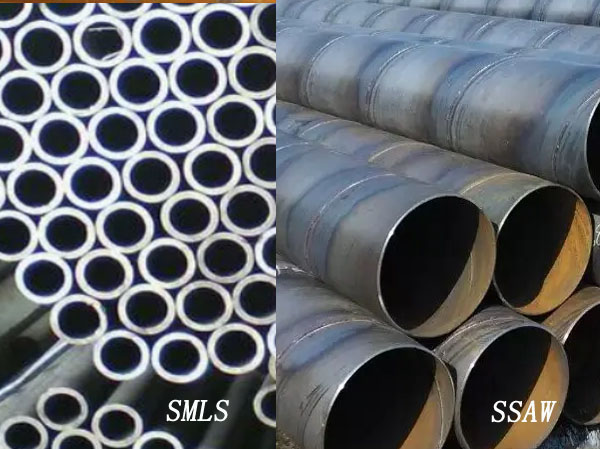

Spiral steel pipes (SSAW) and seamless steel pipes (SMLS) are relatively common pipes in life, and they are used in house decoration and construction. So what is the difference between spiral steel pipes and seamless steel pipes? Then let's find out about it.

What is a spiral steel pipe?

Spiral steel pipe (SSAW) is a spiral seam steel pipe made of strip steel coil as raw material, extruded at regular temperature, and welded by automatic double-wire double-sided submerged arc welding process. The spiral steel pipe sends the strip steel into the welded pipe unit, and after rolling by multiple rollers, the strip steel is gradually rolled up to form a round tube billet with an opening gap. Adjust the reduction of the extrusion roller to control the weld gap at 1~ 3mm, and make both ends of the welding port flush. The appearance of the spiral pipe has spiral welding ribs, which is caused by its processing technology.

What is seamless steel pipe?

Seamless steel pipe (SMLS) is a long strip of steel with a hollow section and no seams around it. It is made of steel ingot or solid tube blank by perforation, and then made by hot rolling, cold rolling or cold drawing. A large number of pipelines are used to transport fluids, such as pipelines for transporting oil, natural gas, gas, water and certain solid materials.

The difference between spiral steel pipe and seamless steel pipe:

1. Different production methods

The seamless steel pipe is made by heating and piercing the tube blank. It has no seams, and the material needs to be determined according to the requirements. The spiral steel pipe is made by heating and rotating the strip steel once, and the material needs to be changed according to the demand. It solves the problem that the seamless large-diameter pipe is not easy to manufacture.

2. Different fields of application

Seamless steel pipes are normally used in high temperature and high pressure fluids, while spiral steel pipes are usually used in fluids below 30 kg, and those with large diameters are used in medium and low pressure fluids. the

Seamless pipes are used in different parts according to different production standards, and are mainly used in industry. Spiral pipes are mainly used in low-pressure water delivery, heat and piling pipes, etc.

3. Different prices

Compared with seamless pipes, the price of spiral pipes is more economical.

Spiral pipes and seamless pipes are different in terms of processing technology, outer surface and usage. Both have their own advantages and disadvantages. You can't blindly save costs without considering the actual use situation. You should choose the best according to your actual situation.