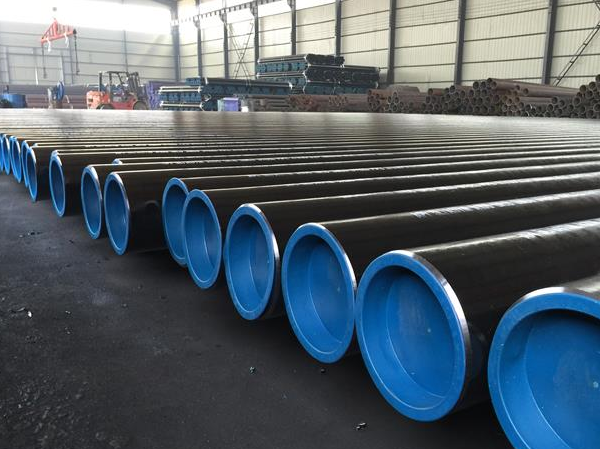

In order to verify the technical performance of

carbon steel seamless pipes (CS pipe), taking into account the requirements of the standard, it is necessary to conduct technical performance inspections on samples of CS seamless steel pipes.

Process performance inspection mainly includes tensile strength, compressive strength, tensile strength, destructive work, etc. Performance index inspection mainly includes extrusion flattening test, flaring test, compression test, wrinkling test, cold drawing test, perforation test, etc. This kind of inspection item has a certain selection according to the different specifications and the difference in the scope of application of CS seamless steel pipes.

Non-destructive testing technology refers to the inspection of internal and surface defects of carbon steel seamless steel pipes without damage. At present, magnetic flux leakage non-destructive testing, ultrasonic flaw detectors, eddy current and fluorescent magnetic particle testing have long been widely used in seamless steel pipe enterprises. In recent years, non-destructive testing technology has a particularly great development trend. Recently, new technologies such as acoustic emission holography, ultrasonic spectrum analysis non-destructive testing, ultrasonic imaging non-destructive testing and ultrasonic high-temperature non-destructive testing have occurred.

The straightness, thickness, curvature, and length of seamless steel pipes can be checked on the inspection ground with external snap gauges, micrometers, curvature levels, and length tapes.

The enlarged opening diameter, thickness and length can also be continuously inspected by automatic size inspection equipment. For OCTG seamless steel pipes, it is also necessary to check the basic parameters of the external external thread.

Generally, estimates are used to inspect the inner and outer surfaces, and the inner surface can also be inspected by using a vertical prism in addition to using estimates. Some

carbon steel pipes with unique scope of application also require non-destructive testing techniques, including eddy current, magnetic flux leakage, ultrasonic, magnetic particle inspection, etc. to inspect the internal and external performance of seamless steel pipes.