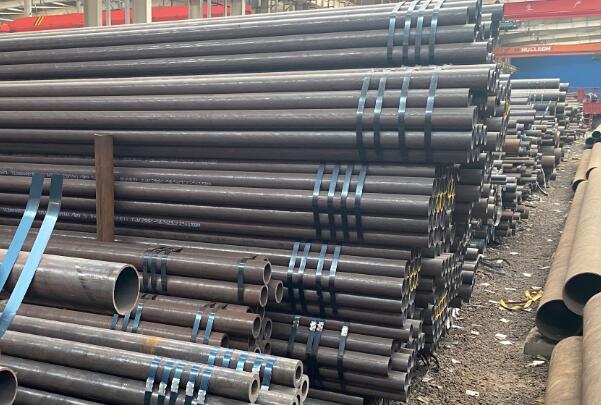

"ERW steel pipe" is Electric Resistance Welded Steel Pipe, abbreviated as ERW. It is used to transport oil, natural gas and other vapor and liquid objects. It can meet various requirements of high and low pressure. It currently plays a pivotal role in the field of transportation pipes in the world. Electric resistance welding has the characteristics of high production efficiency, low cost, material saving, and easy automation. Therefore, it is widely used in various industrial sectors such as aviation, aerospace, energy, electronics, automobiles, and light industry, and is one of the important welding processes.

Difference between Seamless pipe (SMLS) and ERW pipe:

2. Different prices

The price of seamless steel pipe is more expensive than ERW steel pipe and the quality is better. The price of seamless steel pipes of the same specification is generally about 30% higher than that of welded pipes, and the price difference for large diameters is even greater. The required stress of seamless steel pipes can be much higher, and welded steel pipes are generally about 10Mpa, so seamless steel pipes are more expensive.

3. Different quality requirements

Seamless steel pipes have high quality requirements and must be free of internal defects, smooth in appearance, and free of burrs. However, due to the limitations of production methods, defects such as cracks and pores in the welding parts of ERW welded steel pipes are difficult to avoid. The raw materials and precision processing costs of high-quality seamless steel pipes are high, and the prices are correspondingly higher.

4. Cost differences

Since the manufacturing process of seamless pipes is longer and there are more processes, the cost of seamless pipes is always higher than that of welded pipes. ERW straight seam welded pipe is made of cold-bent sheet and then connected together by high-frequency welding. The process is relatively simple and the cost is only a small part of seamless pipe.

5. Different application scope

ERW steel pipe application:

ERW longitudinally welded pipe is mainly used in water supply engineering, petrochemical industry, chemical industry, power industry, agricultural irrigation, and urban construction.

For liquid transportation: water supply and drainage.

For gas transportation: coal gas, steam, liquefied petroleum gas.

For structural purposes: as piling pipes and bridges; pipes for docks, roads, and building structures.

ERW straight seam welded pipes are generally used as wire casings in the power industry. Performance characteristics: 100% ultrasonic testing of the base material to ensure the internal quality of the pipe body; no uncoiling-disc shearing process, base material pressure pit , Less scratches; After the stress is eliminated, the finished pipe basically has no residual stress; the weld seam is short, and the probability of defects is small; it can conditionally transport the moist sour natural gas; After the diameter is expanded, the geometrical size of the steel pipe is high; welding It is carried out in a straight line in the horizontal position after the forming is completed. Therefore, the control of staggered edges, slits, pipe diameter and circumference is better, and the welding quality is excellent.

6. Market demand

Seamless steel pipes are widely used in petroleum, chemical, machinery, rail transportation and other fields. Due to the particularity of use and quantity requirements, the price of seamless steel pipes is relatively high. Affected by market competition and market demand, the price of ERW steel pipes is relatively low.

Generally speaking, seamless steel pipes are more expensive than ERW welded steel pipes. This is because the production process and quality requirements of seamless steel pipes are higher, and the market demand is more specialized. But this does not mean that ERW steel pipes are cheaper in all cases, and it needs to be considered comprehensively according to the specific situation.

Read more: Carbon Steel Pipe Schedule Chart