What is Seamless Steel Tubing?

The seamless steel tube (SMLS) is made of high-quality round steel as the main material, and then the round steel is perforated. The principle of perforation is to use high temperature to soften the round steel, and then use the top head to remove all the solid parts in the middle to become hollow round steel, that is, seamless steel tube.

(1) Hot-rolled seamless tubes are generally produced on automatic pipe rolling units. After checking and removing surface defects, the solid tube blank is cut into the required length, centered on the perforated end face of the tube blank, then sent to the heating furnace for heating, and pierced on the piercing machine. Spin and advance the solid blank inside the process of piercing holes under the influence with the roller as well as the end. Then the solid blank is hollow finally, which is called gross pipe. Send to the automatic pipe rolling machine to continue rolling. Finally, the wall thickness is adjusted by the equalizing machine, and the size is sized by the sizing machine to meet the specification requirements. It is a more advanced method to produce hot-rolled seamless steel tubes by using continuous rolling mills.

(2) If you want to obtain seamless steel tubes with smaller size and better quality, you must use cold rolling, cold drawing or a combination of the two. Cold rolling is usually carried out on a two-roll mill, and the steel tube is rolled in an annular pass formed by a circular hole groove with variable cross-section and a stationary tapered plug. Cold drawing is usually carried out on a single-chain or double-chain cold drawing machine of 0.5-100T.

(3) The extrusion method is to place the heated tube blank in a closed extrusion cylinder, and the perforated rod and the extrusion rod move together to make the extruded part extrude from the smaller die hole. This method can produce steel tubes with smaller diameters.

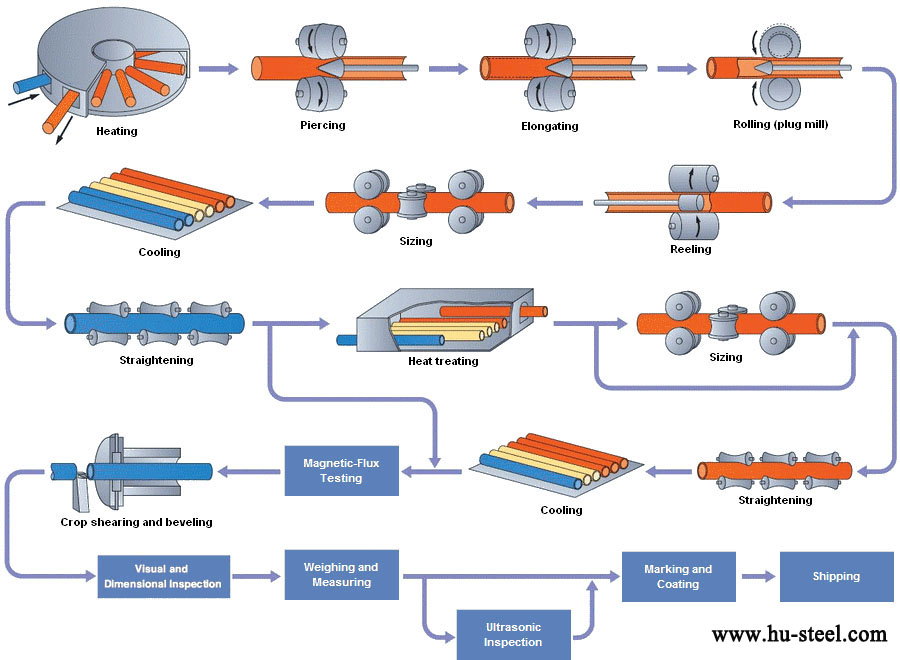

2. Seamless steel tube production process

(1) Hot rolled (extruded) seamless steel tube: round tube billet → heating → piercing → three-roll cross rolling, continuous rolling or extrusion → tube removal → sizing (or reducing) → cooling → straightening →Hydrostatic test (or flaw detection) → marking → storage

(2) Cold drawn (rolled) seamless steel tube: round tube blank→heating→perforation→heading→annealing→pickling→oiling (copper plating)→multi-pass cold drawing (cold rolling)→blank tube→heat treatment→Straightening→hydrostatic test (flaw detection)→marking→warehousing

Seamless steel pipe production process flow chart:

3. The characteristics of different production methods of steel pipes

The extrusion method is to use a piercer to perforate the tube billet or steel ingot, and then extrude it into a steel pipe with an extruder. This method is less efficient than the skew rolling method and is suitable for the production of high-strength alloy steel pipes.

Both the cross rolling method and the extrusion method must first heat the tube billet or ingot, and the produced steel tube is called a hot rolled tube.

Steel pipes produced by hot working can sometimes be cold worked as needed. There are two methods of cold working: one is the cold drawing method, which is to draw the steel pipe through the drawing die to make the steel pipe gradually thinner and elongated; the other method is the cold rolling method, which is invented by the Mennesmann brothers. The hot rolling mill is applied to the method of cold working. The cold processing of seamless steel tube can improve the dimensional accuracy and processing finish of the steel pipe, and improve the mechanical properties of the material.

Read more: Cold Drawn Seamless Steel Tubing or Seamless Tube Production Equipment