Stainless steel seamless pipe (SS seamless pipe) is a long steel material with a hollow cross section and no joints around it. It is a steel pipe resistant to weak corrosive media such as air, steam, water, and chemically corrosive media such as acid, alkali, and salt. Also known as stainless acid-resistant steel pipe.

Features of stainless steel seamless pipe:

1. The thicker the wall thickness of the product, the more economical and practical it is, and the thinner the wall thickness, its processing cost will increase significantly;

2. The process of this product determines its limited performance. Generally, the precision of seamless steel pipe is low: uneven wall thickness, low brightness inside and outside the tube, high cost of cutting to length, and pitting and black spots on the inside and outside are not easy to remove;

3. Its detection and shaping must be processed offline. Therefore, it embodies its superiority in terms of high pressure, high strength, and mechanical structural materials.

The corrosion resistance of stainless steel seamless pipes depends on the alloying elements contained in the steel. Chromium is the basic element for stainless steel to obtain corrosion resistance. When the chromium content in the steel reaches about 12%, the chromium interacts with the oxygen in the corrosive medium to form a thin oxide film (self-passivation film) on the surface of the steel. , can prevent further corrosion of the steel matrix. In addition to chromium, commonly used alloying elements for stainless steel seamless pipes include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc., to meet the requirements for the structure and performance of stainless steel for various purposes.

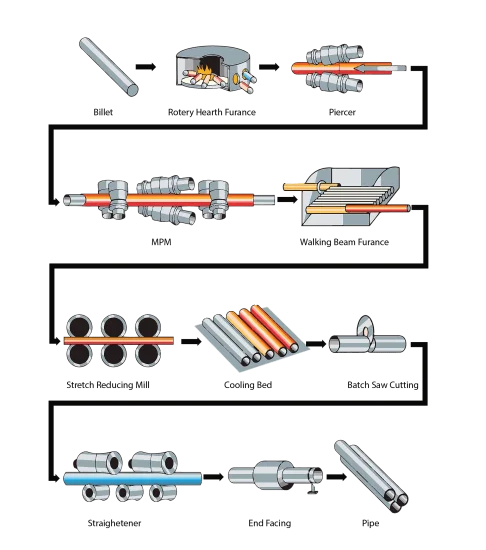

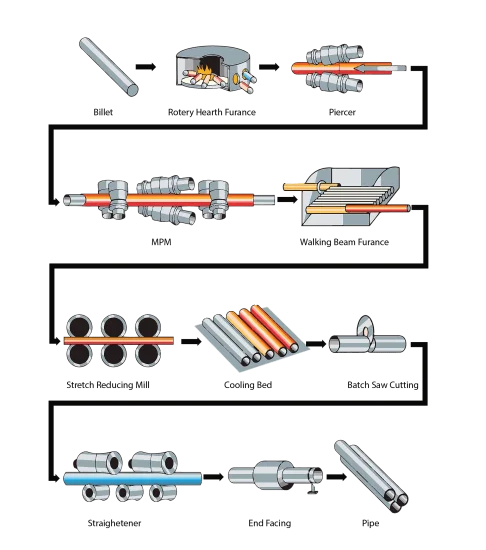

Manufacturing Process of Stainless Steel Seamless Pipe:

According to different manufacturing processes, it can be divided into two categories: stainless steel seamless steel pipe and stainless steel welded steel pipe (seamed pipe).

Production process of stainless steel seamless pipe:

Round steel preparation - heating - hot rolling piercing - head cutting - pickling - grinding - lubrication - cold rolling processing - degreasing - solution heat treatment - straightening - pipe cutting - acid Washing - finished product inspection.

Production process of stainless steel welded pipe:

Raw material--slitting--welding pipe making--repairing--polishing--inspection (printing)--packing--shipping (warehousing) (decorative welded pipe)

Raw material--slitting--welding pipe making--heat treatment--straightening--straightening--repairing--pickling--hydraulic test--inspection (printing)--packing--shipment (warehouse ) (welded pipe for industrial piping)

According to different rolling methods, it can be divided into hot-rolled tubes, cold-rolled tubes, cold-drawn tubes, extruded tubes, etc.

According to the metallographic structure of stainless steel, it can be divided into semi-ferritic and semi-martensitic stainless steel pipes, martensitic stainless steel pipes, austenitic stainless steel pipes, austenitic-ferritic stainless steel pipes, etc.

Hot-rolled stainless steel seamless pipes are generally produced on automatic pipe rolling units. After checking and removing surface defects, the solid tube blank is cut into the required length, centered on the perforated end face of the tube blank, then sent to the heating furnace for heating, and pierced on the piercing machine. Spin and advance the solid blank inside the process of piercing holes under the influence with the roller as well as the end. Then the solid blank is hollow finally, which is called gross pipe. Send to the automatic pipe rolling machine to continue rolling. Finally, the wall thickness is adjusted by the equalizing machine, and the size is sized by the sizing machine to meet the specification requirements. It is a more advanced method to produce hot-rolled seamless steel pipes by using continuous rolling mills.

If you want to obtain

seamless pipes with smaller size and better quality, you must use cold rolling, cold drawing or a combination of the two. Cold rolling is usually carried out on a two-roll mill, and the steel pipe is rolled in an annular pass formed by a circular hole groove with variable cross-section and a stationary tapered plug. Cold drawing is usually carried out on a single-chain or double-chain cold drawing machine of 0.5-100T.

The extrusion method is to place the heated tube blank in a closed extrusion cylinder, and the perforated rod and the extrusion rod move together to make the extruded part extrude from the smaller die hole. This method can produce steel pipes with smaller diameters.

For steel pipes under fluid pressure, a hydraulic test is required to check their pressure resistance and quality. It is qualified if no leakage, soaking or expansion occurs under the specified pressure. Some steel pipes also need to be crimped according to standards or requirements of the buyer , Flaring test, flattening test.

The most common materials for stainless steel pipes are 304/304L stainless steel and 316/316L stainless steel.