Seamless steel pipe (SMLS Pipe) is a continuous metal steel pipe that is made by hot rolling, cold rolling or cold drawing, and is processed into a hollow pipe by perforation or extrusion of solid steel billet. There is no welding process in the whole process, so it is called "seamless". Compared with welded steel pipes, seamless pipes have higher structural integrity and pressure bearing capacity.

Husteel Industry Group provides seamless steel pipes of standard sizes, which are mainly used as petroleum geological drilling pipes, cracking pipes for petrochemicals, boiler pipes, bearing pipes, and high-precision structural steel pipes for automobiles, tractors, and aviation. This is the most common and widely used product, available in various sizes and thicknesses.

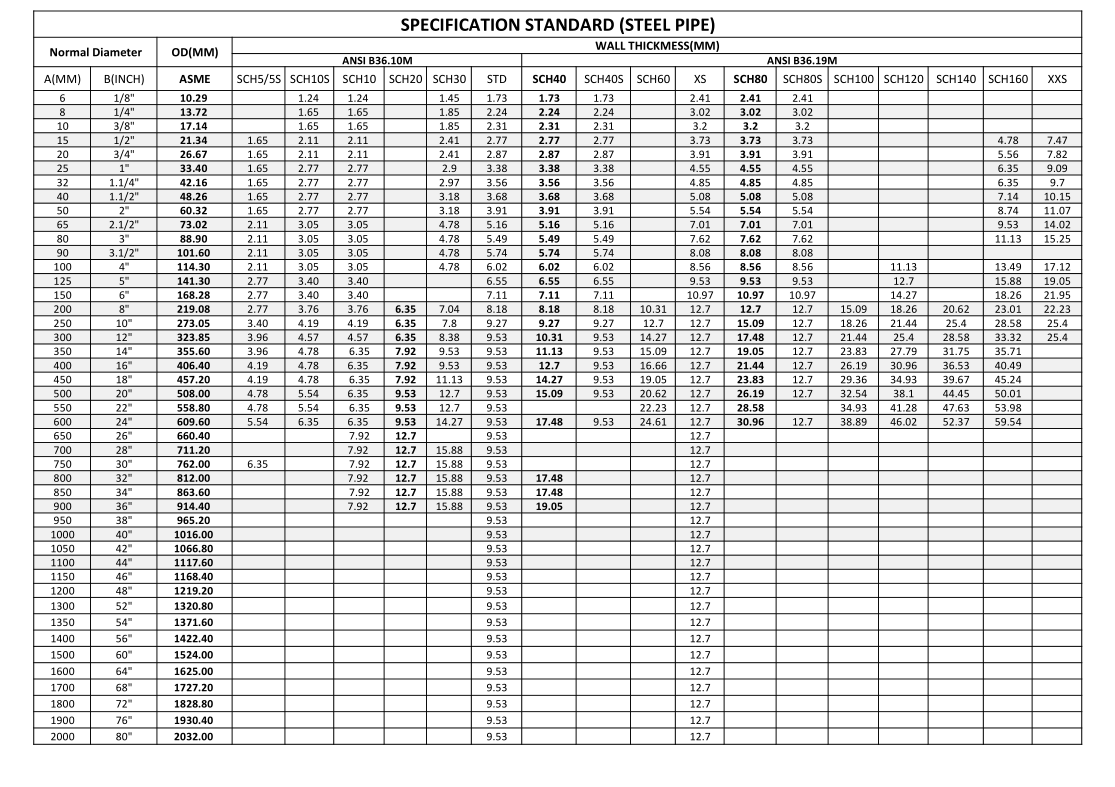

Seamless Steel Pipe & Tube Sizes in mm:

Outer Diameter (OD): 1/4 inch - 36 inch (6.35mm-914.4mm)

Wall thickness (WT): 1.25mm-50mm (SCH10, SCH20, SCH40, SCH60, XS, SCH80, STD, SCH120, SCH160, XXS)

Material Grade: API 5L GR.B, X42, X46, X52, X56, X60, X65, X70 PSL1 & PSL2

Seamless carbon steel pipe size range: 2" - 24"

Seamless carbon steel pipe schedules: STD, SCH100, SCH120, SCH160, XXH

Utilized for the water and petroleum industry to transport liquids or as platforms on off-shore rigs.

Material Grade: ASTM A53 GR.B, ASTM A106 GR.B

Seamless carbon steel pipe size range: 1/8" - 26"

Seamless carbon steel pipe schedules: SCH20, SCH30, SCH40, STD, SCH100, SCH120, SCH160, XXH

Utilized for services ranging from structural supports to steam drum headers with temperature ranges up to 800°F.

Seamless boiler tube outer diameter (OD): 10.2 mm- 139.7 mm

(from 26.9 mm manufactured as hot rolled)

Seamless boiler tube wall thickness (WT): 0.5 mm- 16.0 mm

(from 2.6 mm manufactured as hot rolled)

Seamless Mechanical Tube:

Seamless mechanical steel tube is a high-precision seamless tube designed for the field of mechanical manufacturing, mainly used for key components such as hydraulic systems, bearings, and transmission shafts.

Cold-rolled precision tube outer diameter (OD): 6mm ~ 250mm

Wall thickness (WT): 0.5mm ~ 25mm

Dimension tolerance: ±0.05mm

Cold-drawn finishing pipe outer diameter (OD): 10mm ~ 150mm

Wall thickness (WT): 1.0mm ~ 15mm

Dimension tolerance: ±0.1mm

Seamless Galvanized Tube:

Hot dip galvanized seamless tube outer diameter range: 21.3mm ~ 426mm

Wall thickness range: 2.5mm ~ 25mm

Length: 6m ~ 12m (fixed length)

Zinc layer thickness: ≥85μm (hot-dip galvanized)

Cold-rolled galvanized seamless tube outer diameter range: 6mm ~ 219mm

Wall thickness range: 0.8mm ~ 12mm

Zinc layer thickness: ≥50μm (electrogalvanized)

Note: Extra large diameter (>500mm) requires special order production, thin-walled tubes (<1mm) are mostly electrogalvanized.

Seamless Heat Exchanger Tube:

Seamless heat exchanger tube outer diameter (OD): 6.00 - 101.00 mm

Seamless heat exchanger tube wall thickness: 0.85 mm- 12.7mm

Seamless heat exchanger tube length: 1.0 - 27.0 MTR

Seamless Precision Tube:

Seamless precision tube outer diameter (OD): 10mm - 120 mm

Seamless precision tube wall thickness (WT): 0.5mm - 5 mm

Seamless precision tube length: 4 - 8m

Seamless Hydraulic Tube:

Seamless hydraulic tube outer diameter (OD): 4 - 130mm

Seamless hydraulic tube material: E355 (ST52.4), E235 (ST37.4)

Seamless hydraulic tube standard: DIN 2391/C (DIN EN 10305-1), DIN 2445/2 (DIN EN 10305-4)

Seamless hydraulic tube finishing: NBK (Phosphate and Normalized)

General Size Table of Seamless Steel Pipes and Welded Pipes (mm):

How to calculate the theoretical weight of seamless steel pipe?

The weight calculation of seamless steel pipe is a key link in engineering design and procurement, which directly affects cost accounting and structural load-bearing design.

Weight (kg/m) = 0.02466 × wall thickness × (outer diameter − wall thickness)

Carbon steel density: 7.85g/cm³

Step-by-step calculation example:

Calculate the weight of 20# carbon steel seamless pipe with an outer diameter of 89mm, a wall thickness of 4.5mm, and a length of 6m.

Calculation difference: 89 - 4.5 = 84.5mm

Substitute into the formula: 0.02466 × 4.5 × 84.5 ≈ 9.38 kg/m

Total weight (W): 9.38 × 6 = 56.28 kg

Note:

Deviation between theoretical value and actual value: Due to the dimensional error allowed by the production process (such as wall thickness deviation), the theoretical weight is only used as an estimated reference.

Adjustment of special materials: Materials with large density differences such as stainless steel need to adjust the coefficient value. The calculation formula needs to be multiplied by the ratio of the material density to 7.85.

Key points for selecting seamless steel pipe sizes:

1. Wall thickness selection (working pressure)

High pressure/high temperature environment (e.g. 10MPa): Select Sch80, Sch160 (thickened wall thickness).

Low pressure fluid (0.6MPa): Select Sch40 (standard wall thickness).

2. Matching of outer diameter and inner diameter

Pipe diameter (DN) ≠ outer diameter, which needs to be converted according to the standard (especially the difference between American standard NPS and national standard DN).

The flange and valve interface must be consistent with the outer diameter of the steel pipe, otherwise the inner diameter needs to be reduced.

3. Temperature and material selection

The performance of carbon steel varies greatly at different temperatures, and the materials need to be matched:

-20℃~350℃: 20# steel, low carbon steel, good low temperature toughness.

350℃~550℃: 15CrMoG, alloy steel, resistant to high temperature oxidation.

≤-20℃: 16MnDG, A333 Gr.6 low-temperature steel, resistant to brittle cracking.

Key points:

Carbon steel will graphitize if used above 400℃ for a long time, and alloy steel (such as 12Cr1MoVG) must be selected.

Low-temperature environments (such as LNG) require Charpy impact tests (≥27J) to verify toughness.

4. Outer diameter tolerance

Hot-rolled tubes: ±1%~1.5%.

Cold-drawn tubes: ±0.1%~0.5% (high precision).

5. Special needs

Corrosion resistance: Choose galvanized seamless tubes or stainless steel composite tubes.

Lightweight: Consider thin-walled cold-drawn tubes (wall thickness ≤2mm).

Cost comparison:

Preferred standard sizes: Prefer ASME standard sizes such as Φ48.3 and Φ114.3 (sufficient inventory, 20% lower price)

The cost of galvanized carbon steel pipes is less than 50% of that of stainless steel pipes, but the life is shorter.

Chemical strong acid environment → directly choose Hastelloy C276, which has higher reliability.

Testing and verification requirements:

Required inspection items:

Hydraulic pressure test: 1.5 times the design pressure, pressure maintenance for 10 minutes

Ultrasonic testing: can detect defects ≥Φ1.6mm

Special testing:

Intergranular corrosion test (stainless steel)

Hardness test (alloy steel heat treatment verification)

Read more: Schedule 40 vs Schedule 80 Pipe or China Seamless Steel Pipe Manufacturer List